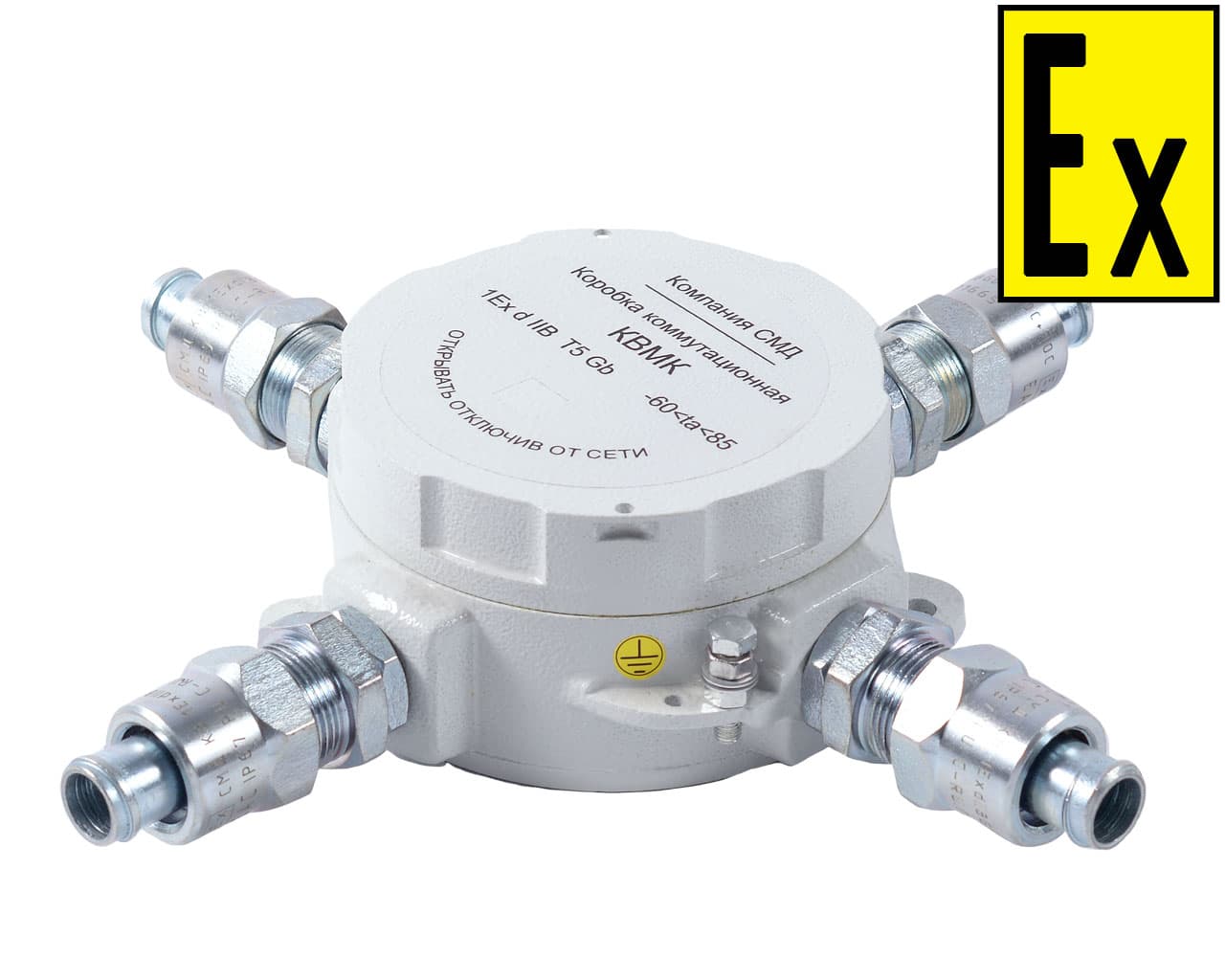

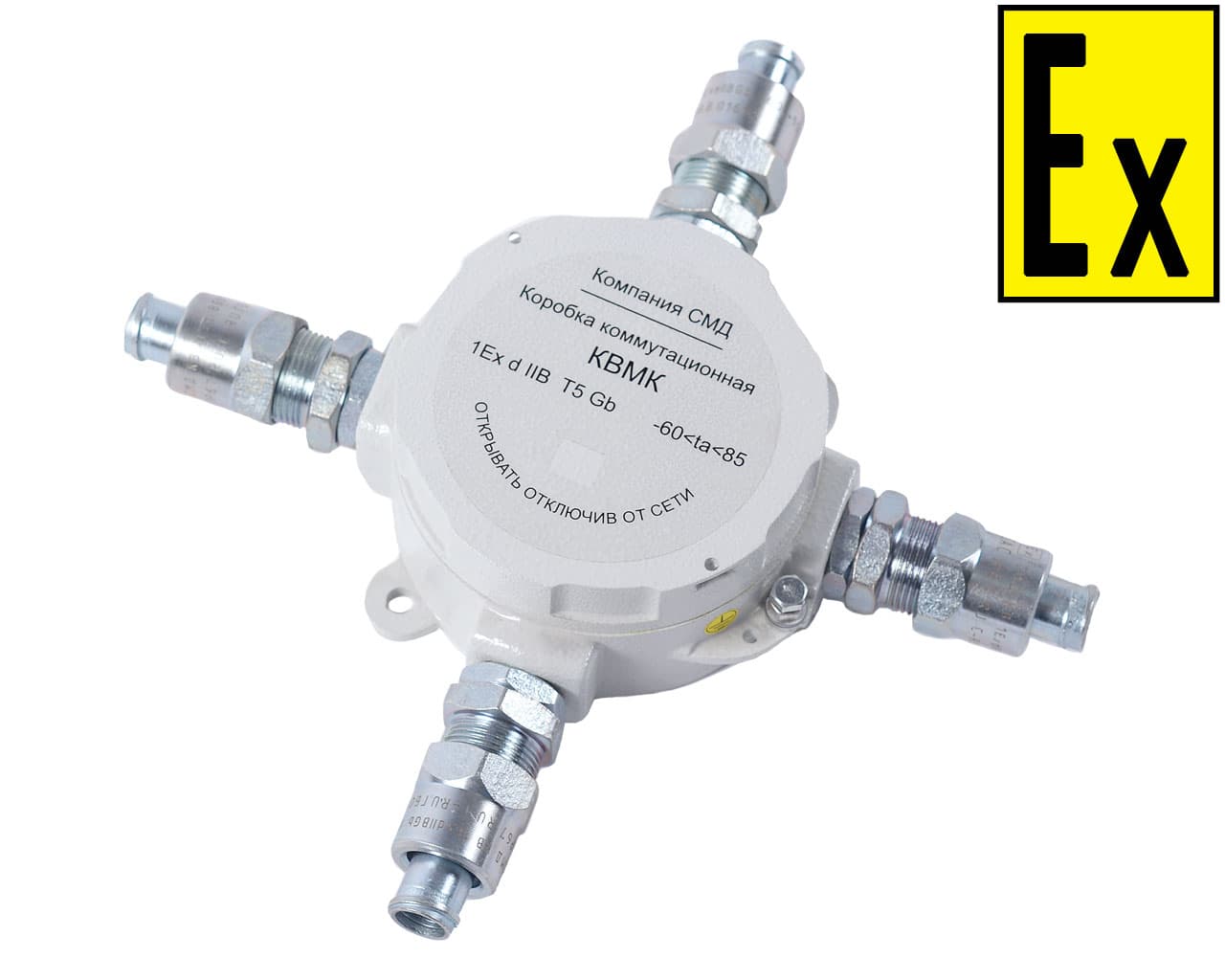

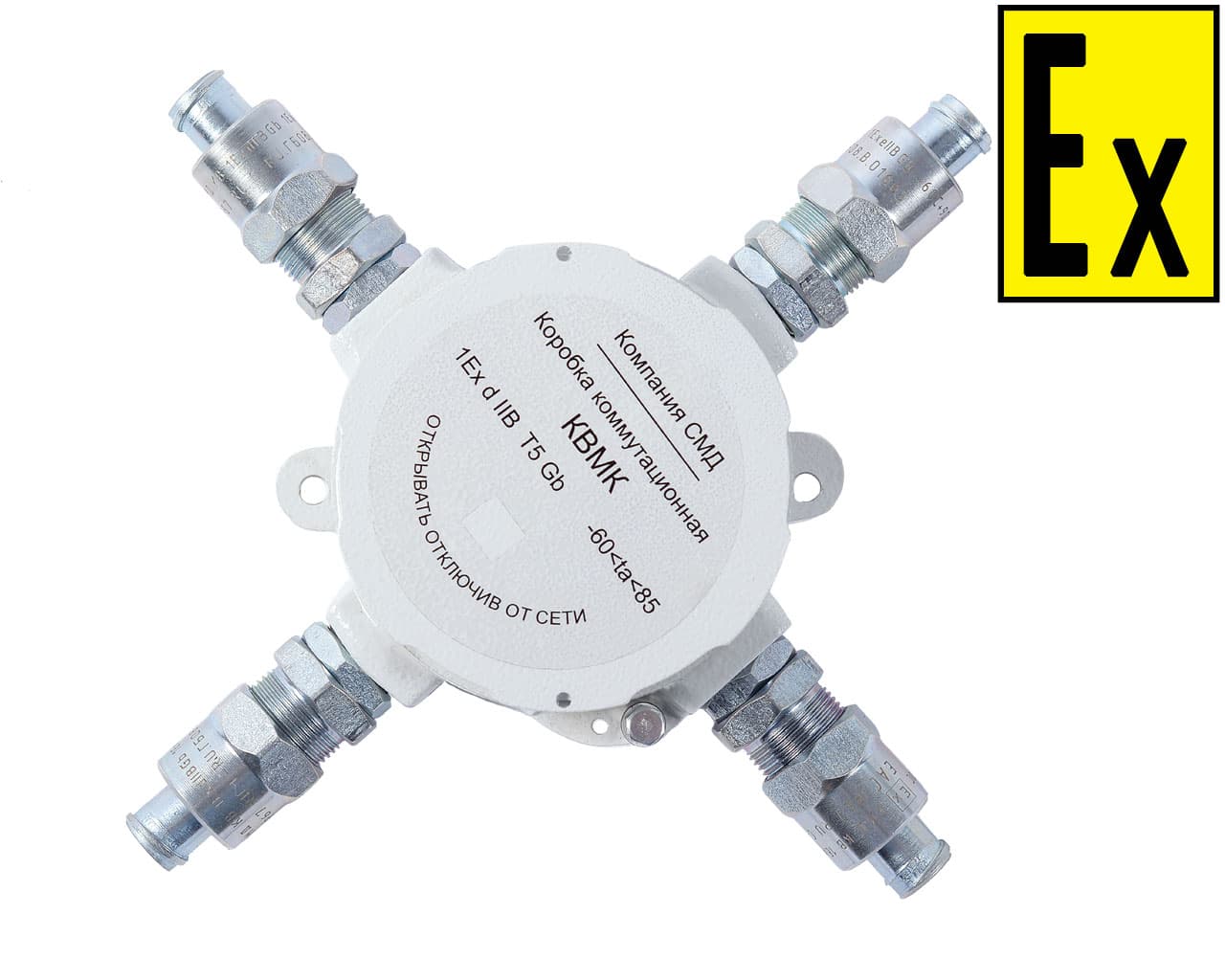

Explosion-proof boxes are designed to make connections (branches) of general and special-purpose electrical circuits (power circuits, control circuits, signaling, etc.) in explosion-hazardous areas. The boxes are used to input armoured, unarmoured electrical cables of round or flat cross-section and cables in a metal sleeve.

The material used for the production of boxes and Ex-components is aluminum alloy or stainless steel.

The boxes are provided with the following types of explosion protection: GOST IEC 60079-1-2013 "flameproof enclosures "d"" and GOST IEC 60079-31-2013 equipment with dust ignition protection by enclosures "t".

The boxes have various options of explosion-proof connections in accordance with the requirements of GOST IEC 60079-1-2013, are manufactured both by welding for stainless steel and by casting for aluminum alloy. The viewing window is located on the front cover of the case.

The boxes are classified as electrical equipment of groups I, II and III according to GOST 31610.0-2014 and are intended for use in hazardous areas of premises and outdoor installations in accordance with the explosion protection marking. The equipment can be used in hazardous areas of classes 0, 1 and 2 according to GOST IEC 60079-10-1-2011, as well as in mines and pits GOST 31439-2011 (EN 1710:2005). The environment may contain explosive mixtures of gases and vapors with air of category IIA, IIB, IIB+H2, IIC, dust IIIC

|

Series name |

Model name |

Body material |

Ex-marking according to |

||||

|

Boxes switching series – KVMK. |

KVMK 3.1 Exd-A - XXX… X |

Stainless steel. |

|

||||

|

Stainless steel. Aluminum alloy. |

|

||||||

| - The equipment designation plate must indicate the specific temperature class for group I (T6/T5/T4/T3) and group II (T80 0 C, T90 0 C, T130 0 C, T190 0 C) based on the Ex marking. - The “X” sign at the end of the name indicates the overall dimensions of the body and the dimensions of the viewing window. |

|||||||

|

Switching box of the KVMK series, |

|||||||

| Marking of explosion-proof boxes | |||||||

| Marking for stainless steel for electrical equipment group I, II and III |

|

||||||

| Marking for aluminum alloy for electrical equipment group II and III |

|

||||||

| Marking of explosion-proof enclosures. | |||||||

| Marking for stainless steel for groups I, II and III |

|

||||||

| Marking for aluminum slava for groups II and III |

|

||||||

| Body material |

stainless steel aluminum alloy |

||||||

| Housing material for mine design |

stainless steel |

||||||

| Type of explosion-proof connection |

threaded connection |

||||||

| Internal volume, cm3 |

no more than 2000 |

||||||

| Degree of protection of the shell according to GOST 14254-2015 |

IP66/IP67 |

||||||

| Ambient temperature under operating conditions |

T6 - from -60 0 C to +80 0 C |

||||||

| Temperature class according to GOST 31610.0-2014. |

T6, T5, T4, T3 |

||||||

| Climate performance |

HL (F), UHL (NF), OM (MU) |

||||||

| Switching current, A - alternating current - direct current |

no more than 800 no more than 800 |

||||||

| Switching voltage, V - alternating current - direct current |

no more than 1000 no more than 1000 |

||||||

| Overall dimensions of the shell, mm |

100x100x60mm – code in designation 101006 100x100x90mm – code in designation 101009 |

||||||

|

Name of the junction boxes of the KVMK series, |

Name of the shells of the SMD MK series, |

||||||

|

Aluminum alloy |

Stainless steel |

Aluminum alloy |

Stainless steel |

||||

|

KVMK 3.1 Exd-A-101006 |

KVMK 3.1 Exd-N-101006 |

SMD MK 3.1 Exd-A-101006 |

SMD MK 3.1 Exd-N-101006 |

||||

|

KVMK 3.1 Exd-A-101009 |

KVMK 3.1 Exd-N-101009 |

SMD MK 3.1 Exd-A-101009 |

SMD MK 3.1 Exd-N-101009 |

||||

Conventional designation of the name applied to the marking plate:

|

KVMK |

4 |

1 |

Exd |

- A - |

X 1 X 2 … X n |

- Y 1 Y 2 … Y n |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

KVMK – explosion-proof junction box.

3 – standard case; 4 – enlarged case.

1 – threaded connection.

Exd – "flameproof enclosures "d".

A – aluminum alloy. H – stainless steel.

Files to download: